Thu July 30, 2020

Mammoet

A joint venture between Mammoet and Giant Heavy Machinery Services has started working with Sing Da Marine Structure Corporation, a marine engineering subsidiary of China Steel Corporation to provide assembly, transportation and load-out services for Taiwan's first locally fabricated wind turbine jacket foundations, on site at its manufacturing facility.

Sing Da Marine Structure Corporation said, "We are excited to leverage Mammoet-Giant JV's engineering expertise to assist us with the design of lifting arrangements that will ensure efficient and safe operations. Mammoet-Giant JV's wide range of lifting and transport technology is enabling time and cost efficiencies for this project."

Mammoet-Giant JV will be performing the assembly, transportation and load-out of the jackets, which each weigh approximately 1,322 tons (1,200 t).

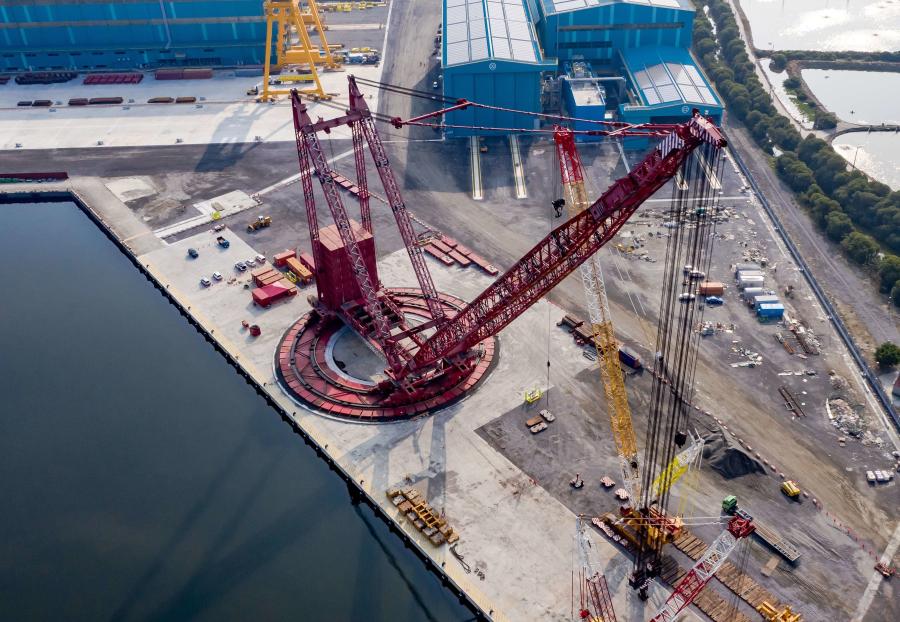

The PTC200-DS Ring Crane will assemble the jackets by first upending the lower jacket structure before installing both the upper structure and transition pieces at a single location.

Seventy-two axle lines of SPMT will then transport each jacket up to 3,937 ft. (1,200 m) from the jacket fabrication line to a storage area.

Four jackets are expected to be simultaneously assembled near the PTC200-DS Ring Crane while the crane also will complete multiple heavy lifts to load-out each jacket onto the barge, thus increasing time efficiency for this project.

The project is a joint effort between SDMS and renewable energy company Ørsted, with the aim to deliver jacket foundations and knowledge transference to develop Taiwan's offshore wind supply capacity.

For more information, visit www.mammoet.com.

PTC200-DS crane ready for the assembling and lifting of the wind turbine jackets onto the barge.

Cranes Equipment

Cranes Equipment Articles

Articles Email Updates

Email Updates Sell Your Machines

Sell Your Machines

Cranes Equipment

Cranes Equipment Cranes Dealers

Cranes Dealers Cranes Articles

Cranes Articles Email Updates

Email Updates Sell Your Machines

Sell Your Machines